Description

Performance without compromise

- CleanDrive: stable excitation in air and liquid

- Ultra-low noise

- Direct drive: high-resolution imaging and large scan area

- Fully motorized system: full control via software

CleanDrive: stability in air and liquid with photothermal excitation

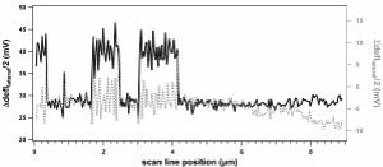

Photothermal excitation of the cantilever provides unparalleled stability, a linear frequency response, and a high excitation bandwidth in air and liquid environments. These benefits allow measurements at multiple frequencies and highspeed applications and open new horizons for innovative new measurement modes (e.g. Cytomass Monitor).

These advantages are amplified in liquids since only the cantilever beam is excited and the liquid environment remains largely unperturbed. This results in clean resonance peaks and not the “forest of peaks” commonly seen with the piezo acoustic excitation of cantilevers. Furthermore, this method of exciting the cantilever is insensitive to changes in the environment and distance to the sample, making the whole measurement system much more stable.

The DriveAFM, with its small light spots, is compatible with the use of small cantilevers, which have several advantages that make them superior in performance. While they have the same spring constant as a conventional cantilever, small cantilevers show a significantly higher resonance frequency and operational bandwidth. Also, the noise performance is better. Due to the small dimensions, the sensitivity is increased, and hydrodynamic drag is decreased. All of this results in better imaging performance.

Ultra-low noise

The DriveAFM has a very low overall noise floor, which is achieved through a combination of a low-noise/low-coherence superluminescent diode and a low-noise/high-bandwidth photodetector used in the beam deflection detection module and the low-noise/high-bandwidth CX Controller. This is the basis for the stable, sensitive, and high-resolution imaging and force spectroscopy capability of the DriveAFM.

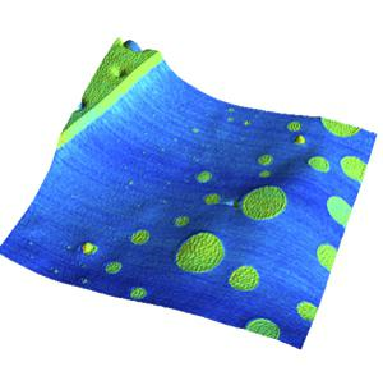

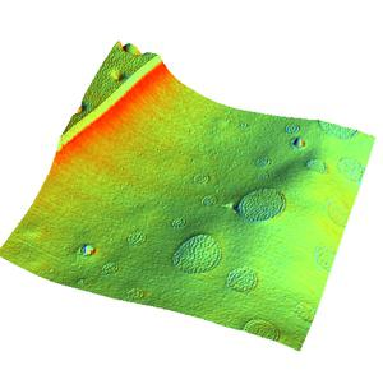

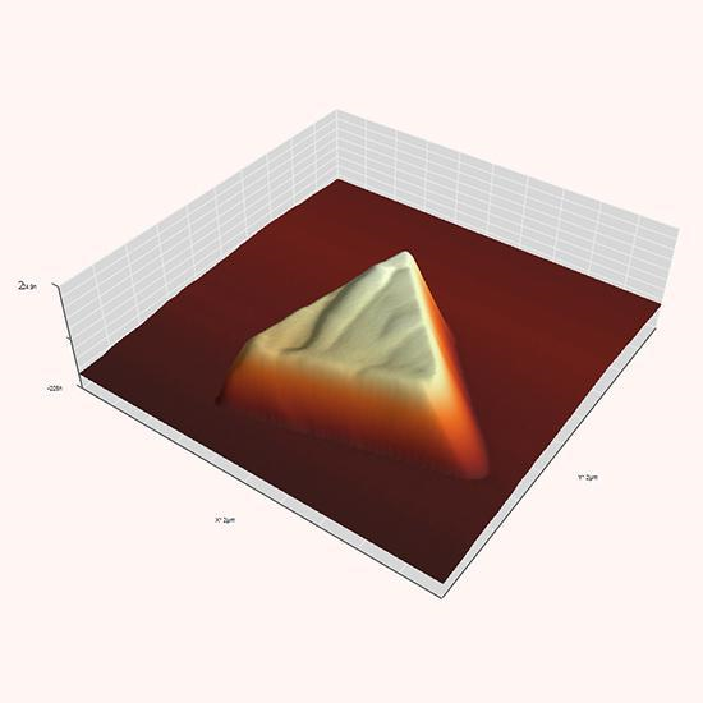

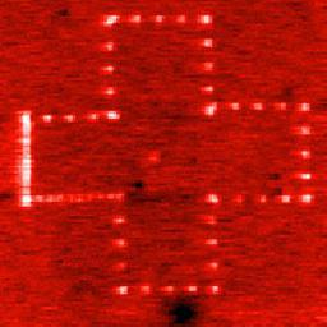

The DriveAFM exploits the power of direct drive piezo actuation. The 1:1, non-geared actuation scheme of the DriveAFM’s flexure scanner provides more force and can drive stiffer scanners. The resulting higher resonance frequency of the scanner components allows for a higher available actuation bandwidth than with geared drives of the same scan size. The direct drive scanner actuation in combination with the low noise 28-bit CX Controller allows for both imaging at large scales and at high resolution. The DriveAFM is the perfect solution for high-resolution imaging of demanding samples such as nanostructures, proteins, or polymeric structures (e.g. DNA), and also for larger, micrometer-sized structures.

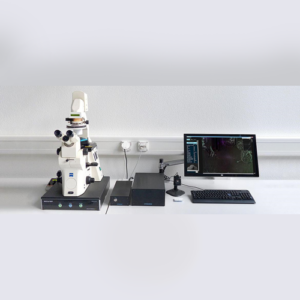

Full motorization

The DriveAFM is the first fully motorized AFM system that can be integrated with an inverted optical microscope. The adjustment of the two light sources for the beam deflection detection system and the CleanDrive photothermal excitation, as well as the photodetector, are fully motorized and can be controlled from the software. The tip approach to the sample is also motorized. The full motorization not only contributes to the ease of use but also allows new possibilities to fully automate the system.

DriveAFM imaging modes

This overview shows which modes the instrument is capable of. Some modes may require additional components or software options. For details, please view the brochure or contact us directly.

Static Force Mode

Lateral Force Mode

Dynamic Force Mode (Tapping Mode)

Phase Imaging Mode

Magnetic properties

Magnetic Force Microscopy

Electrical properties

Conductive AFM (C-AFM)

Piezoelectric Force Microscopy (PFM)

Electrostatic Force Microscopy (EFM)

Kelvin Probe Force Microscopy (KPFM)

Mechanical properties

Force Spectroscopy

Force Modulation

Stiffness and Modulus

Adhesion

Unfolding and Stretching

Force Mapping

Lithography and Nanomanipulation

Electrochemical AFM (EC-AFM)

| Scan head | |

|---|---|

| Scan size | typ. typ. 100 µm x 100 µm x 20 µm min. 95 µm x 95 µm x 18 µm |

| Read-out light source | 850 nm low-coherence SLD |

| CleanDrive light source | 785 nm laser |

| Photodetector bandwidth | ≥8 MHz |

| Standard / maximum sample size | 100 mm / 150 mm |

| Z-height noise dynamic | <30 pm (RMS) |

| Z-height noise static | <30 pm (RMS) |

| DC detector noise* | <5 pm (RMS, 0.1 Hz – 10 kHz) |

| AC detector noise* | <25 fm/√(Hz) above 100 kHz |

| Approach | 10 mm motorized, parallel |

| (*) measured with a USC-F1.2-k7.3 cantilever | |

| CX Controller specifications | |

|---|---|

| High resolution outputs (DAC) | 12x 28 bit, 1 MHz/sampling; thereof 4x user DAC (optional) |

| Fast outputs (DAC) | 4x 16 bit, 100 MHz/sampling; thereof 1x user DAC (optional) |

| High resolution inputs (ADC) | 12x 20 bit, 1 MHz/sampling; thereof 4x user ADC (optional) |

| Fast inputs (ADC) | 3x 16 bit, 100 MHz/sampling; thereof 1x user ADC (optional) |

| Signal analyzers | 2 signal analyzer function blocks that can be configured as dual channel lock-in |

| FPGA module and embedded processor | System-on-chip module with low-latency FPGA signal processing at 100MHz and dual-core ARM processor, 2GB RAM, 1.5GHz clock |

| Scan control | 28-bit X/Y/Z-DAC |

| Detector inputs | Deflection/lateral signals each 20 bit |

| Digital sync, Spike-Guard | 2-bit line/frame sync out 5 V/TTL galvanically isolated, Spike-Guard input |

| Clock sync | 10MHz/3V clock input to synchronize data acquisition and processing |

| Communication to PC | Gigabit Ethernet, galvanically isolated |